Coal Mill Operation, Power Plant

Coal Mill Operation, ... Coal Hangup in Bowl Mill Operations ... This is the first mathematical model of power plant Tubeball mills to cover the whole milling ...

WhatsApp)

WhatsApp)

Coal Mill Operation, ... Coal Hangup in Bowl Mill Operations ... This is the first mathematical model of power plant Tubeball mills to cover the whole milling ...

The primary air input to a ball tube mill ... The IEA carries out a comprehensive programme of energy cooperation A project to examine coalfired power ...

Coal Pulverizer Maintenance Improves Boiler Combustion; ... All fuel lines must be sampled and the fineness sieved from each coal pipe ... such as ball tube mills ...

Anthracite Vertical Roller Mill Operation. Coal required grinding by the central coal feeding tube into the millstone central, ...

Coal Tube Mills Operation Crusher USA. About coal tube mills operationrelated information:alstom mill solutions for gypsum grinding. raymond® imp™ mill ...

coal ball tube mill bbd operation, coal ball tube mill bbd operation what is the reason for frequently explosion in coal mill BBD 4772 (ball Tube mill ...

Coal Hangup in Bowl Mill Operations, ... A new modelbased approach for power plant Tubeball mill, plant operation flexibility have posed new challenges to the ...

Feb 23, 2010· Here''s a 3D animation of how a coal grinding system works. Williams Crusher has the most advanced direct fired coal and pet coke pulverizing system in ...

Improving Coal Pulverizer Performance and Reliability. A p p l i c a t i o n U p d a t e Introduction Power generation industry studies have shown that coal ...

Balancing Coal Pipes. ... transport velocity throughout the entire range of mill loading/operation. ... the system is doing be seen and coal pipe balancing ...

The four most common types of coal pulverizers are: BallTube Mills This type of mill consists of a rotating tube ... operation of the power plant, it is critical

ring and ball mill for pulverisation of coal pdf YouTube coal tube mill operation,8 May 2014, Ball and tube mills; Mill construction details; Operation Medium ...

INTRODUCTION TO BOWL MILLS: Coal is the one of the most dominating energy ... Ball Tube Mill ... Principle of Operation: Bowl Mill is driven by AC ...

Mill Steam Inerting System Review and Performance Validation by ... During operation, ball tube mills and vertical roller ... and a ball tube mill. Raw coal .

Tarpaulin Tender TenderTiger bbd4772 coal mill operation,Annual maintenance of CI/ premier pipe line work at colony premises at TPS Repairs to HP pump of coal ...

Coal Tube Mill Operation pretstudyorg. This page is about coal tube mill operation, click here to get more infomation about coal tube mill operation coal ball mill ...

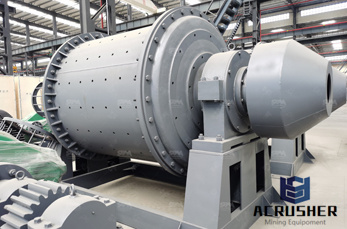

Tube Mill for Coal Ore, ... Tube ball mill reliable working condition milling large capacity easy and safe operation environmental protection. Tube ball mill.

Online coal and primary air flow measuring devices can be helpful to more precisely balance pipetopipe coal and air flows. Some utility customers have adopted on ...

This page is about coal tube mill operation, click here to get more infomation about coal tube mill operation. » Learn More. coal mill operation YouTube.

Performance Driven Maintenance of Coal Pulverizers ... Pulverizer performance testing provides insight to operation and ... This was a ball tube mill and the issues ...

Coal Tube Mill Operation pretstudyorg. coal ball mill operation Mine Equipments, These have impacted the coal mill and power plant operation safety and ...

Ball Tube Coal Mill Modernization and Performance Components. Increase throughput, balance coal pipes, increase coal fineness, reduce emissions.

capacities of coal Reliable, longlasting operation Simple, ... 13 Reject cone with return pipe ... sumption of an ATOX coal mill based

Ball tube mill. Ball tube mills are either pressurized or suction type. In the pressurized type, the hot primary air is used for drying the coal and to transport the ...

WhatsApp)

WhatsApp)